Thank you for Subscribing to Chemical Industry Review Weekly Brief

Chemical Industry Review: Specials Magazine

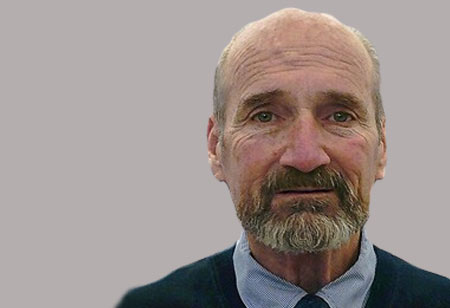

The Shepherd Color Company has spent almost a century shaping the future of high-performance complex inorganic color pigments. As a fifth-generation family-run business, Shepherd Color creates pigments tailored to the precise needs of industries such as paints and coatings, plastics and ceramics. Its focus on performance-driven solutions has propelled it to the forefront of the global pigments market, distinguishing the company as an indispensable partner for businesses seeking high-performance, durable and long-lasting colorants. Today, Shepherd Color thrives under the leadership of Tom Shepherd and his children, who continue to honor the company’s core values—demonstrating exemplary character, striving for excellence, and working for long term impact. Their unwavering dedication to brightening lives is the guiding principle that drives every facet of its operations, from exceptional product development to world-class customer satisfaction. The company’s strong emphasis on customer service is built on decades of trusted relationships. Many of these partnerships have lasted over 50 years, enabling mutual growth as the company and its customers thrive together. This enduring trust and collaboration have strengthened Shepherd Color’s standing as a leading provider of high-performance inorganic color pigments, trusted by clients who value reliability and longevity. Color Solutions for Extreme Durability The company develops these pigment solutions for highly demanding applications, particularly in the architectural exterior coatings market. Unlike traditional paints, which prioritize price over durability, Shepherd Color’s innovative pigments are designed to enhance the longevity of exterior finishes like stucco, siding, and metal roofing, offering robust protection against weathering and fading. For example, in the metal building industry, commonly known as the coil coating industry, the requirements for coatings’ film thickness was very thin, but existing pigments were too large. Shepherd Color developed pigments tailored specifically for these applications by reengineering its particle size control and manufacturing processes, and becoming the standard for use in this application. “Not only do we solve client issues, but there are instances where we assist them with challenges unrelated to our products, ensuring their success as a part of our commitment to exceptional service,” says Chris Manning, President.

Top Oligomer Products Supplier 2025

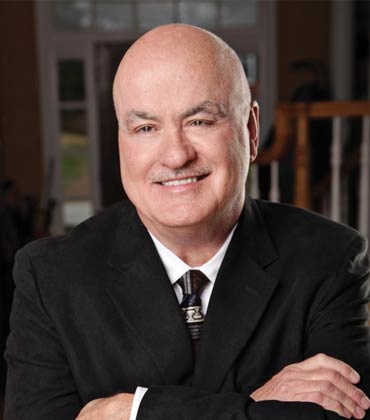

The turn of the 21st century unlocked a new era in the microelectronics industry, characterized by increasing performance expectations and stricter global manufacturing standards. Customer demands rapidly evolved, highlighting the need for improved adhesive resins for packaging applications and advanced technology for higher-frequency applications. As businesses strived to keep up, Designer Molecules, Inc. (DMI) developed superior organic solutions that shaped the next generation of advanced microelectronic materials. A global developer of reactive monomers and functional oligomers, DMI solves complex processing and performance challenges for advanced materials through novel reactive chemistries. Its products are predominantly used in microelectronics to support wafer fabrication, packaging and printed circuit board applications. “Our products consistently outperform commercially available alternatives because we rely on our sales team to collect customer feedback and integrate their insights into our development process from the start,” says Frank D. Husson, Jr., president and CEO. DMI’s product innovations are centered on reactive chemistries that offer thermal stability and low moisture uptake—critical attributes for high-reliability electronics. Over the years, the company has focused on numerous key development areas and curated a library of compounds. The synthesis of imide-extended bismaleimide (BMI) oligomers with aromatic, aliphatic and cycloaliphatic backbones is one of its many breakthroughs. These thermoset materials outperform conventional epoxy resins, particularly in high-temperature lead-free solder reflow conditions of up to 260°C. Their inherent hydrophobicity helps adhere to stringent moisture resistance benchmarks. BMI-based materials also exhibit low dissipation factors (Df values ≤0.003), essential for enabling high-frequency applications like 5G communications, radar systems and automotive sensors. Its acrylate- and methacrylate-terminated oligomeric polyesters also meet the requirement for thermal stability at 260°C solder reflow. These polyesters are suited for use as temporary adhesives in silicon wafer back-side grinding. In addition, the colorless variants of its methacrylate-terminated oligomers have shown significant promise in dental composites and orthodontic applications. DMI’s chemical acumen is best highlighted in the development of a military-grade conductive adhesive. The application required an electrical conductivity level that traditional silver-filled die-attach adhesives couldn’t provide. Its in-house chemists developed a solution using soluble palladium itaconate (SPdl), a novel palladium-containing molecule that decomposes at 160°C during cure.

Chemical Manufacturing Company 2025

Most chemical providers stop at delivery. Hydrite begins there. As a vertically integrated manufacturer, Hydrite does more than produce a broad range of industrial and specialty chemicals—it embeds itself into the operational fabric of its clients. Across food processing, water treatment, agriculture and more, it ensures every chemical solution it delivers is aligned with specific performance goals, regulatory requirements and real-world constraints. With in-house production, custom formulation, and technical field support under one roof, Hydrite offers full visibility and control from formulation to application, bringing measurable gains in precision, efficiency, and compliance. Hydrite’s industry-specific expertise strengthens this end-to-end capability. Instead of selling generic products into complex environments, it tailors every engagement to meet each sector’s technical and regulatory nuances. In food processing, Hydrite supports sanitation, membrane treatment and defoaming programs built around food safety and product integrity. Agriculture’s adjuvants, water conditioners and fertilizer additives are designed to optimize field performance while ensuring environmental compliance. While in water treatment, Hydrite develops targeted chemical programs to manage pH, remove contaminants and maximize system uptime. Each solution is backed with sector-specific knowledge, ensuring every recommendation is as operationally sound as scientifically validated. That level of precision doesn’t happen by accident. It’s enabled by Hydrite’s internal R&D and custom formulation capabilities, which sit at the heart of the company’s value proposition. Hydrite operates its labs, staffed by chemists and field experts who co develop solutions with clients. Whether reformulating a defoamer due to a shift in raw materials or engineering a clean-in-place (CIP) system to meet updated food safety standards, Hydrite treats formulation as a collaborative, iterative process. The result is a level of agility and customization that offthe-shelf suppliers can’t match—one that helps customers navigate change without sacrificing control.

CXO INSIGHTS

How To Make The Most Of Your Process Failure Mode And Effects Analysis

Monte Heisler, Director, Manufacturing Quality, North American Stamping Group

Aiming For An Energy-Efficient World

Trent Randles, Engineering Manager, BorgWarner

Flexibility To Change Is The Key To Successful Pharma Projects

Carrie Lewis, Executive Director, Clinical Program Optimization, Endo Pharmaceuticals plc

High-Performing Teams in the Built Environment

Joseph Yost, Vice President Strategic Initiatives, McCarthy Building Companies, Inc

Asbestos Inside Our Homes

Denio Sturzeneker, Corporate Safety Director, Plaza Construction

From Concept to Counter, Flawlessly Executed

Lauren Albanese, Global Director of Product Development, Procter & Gamble (P&G) [NYSE: PG]

Engineering the Future of Genetic Medicine Through Safety-Led Innovation

Jason Gatlin, Director RGM R&D Chemistry, Regeneron

IN FOCUS

Navigating the Landscape of Inorganic Color Pigments Manufacturing

The inorganic color pigments industry, long known for providing durable, vibrant colors to a wide range of applications, is experiencing a significant transformation.

EDITORIAL

Transforming the U.S. Chemical Industry through Innovation

However, U.S. chemical companies are facing several challenges today. Rising costs from stricter environmental regulations, inflation, and global competition are pressuring margins. For years, U.S. producers benefited from low-cost shale gas, especially ethane, which gave them an edge in making petrochemicals. However, stricter Environmental Protection Agency (EPA) rules raise business costs.

Additionally, global disruptions such as geopolitical conflicts, pandemics, and logistical delays continue to impact supply chains. These disruptions have made sourcing raw materials and delivering finished products more expensive and less predictable.

Technology is also reshaping the industry. Tools like artificial intelligence (AI), smart sensors, and automation are helping companies improve efficiency and safety. However, adopting these new technologies takes time, money, and skilled workers—things not all companies have in abundance.

Despite these headwinds, the industry remains optimistic. The U.S. chemical industry is entering a transformative era that prioritizes sustainable growth and long-term value creation. Emerging areas such as specialty chemicals, green hydrogen, bio-based materials, and advanced recycling offer substantial new opportunities. Companies strategically investing in innovation and aligning with robust environmental, social, and governance (ESG) standards will be best positioned to lead in this evolving landscape.

In this issue, we examine the evolution of the U.S. chemical industry. We feature insights from leaders like Rocky Plemons, Vice President of Construction and Integrated Services at Fluor Corporation [NYSE: FLR], and Nicole Voss, Director of Sustainability at Advanced Drainage Systems, Inc. Their experiences offer valuable lessons on how to navigate challenges and seize new opportunities in this ever-changing industry. We hope these valuable insights from industry leaders featured in this edition will assist you in making informed decisions for your businesses.