Thank you for Subscribing to Chemical Industry Review Weekly Brief

Chemical Industry Review: Specials Magazine

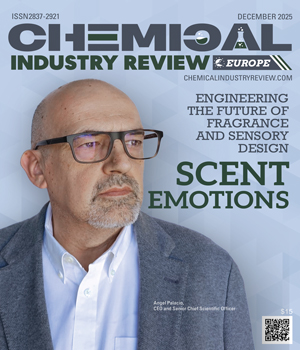

Scent Emotions is leading the future of multisensory product design, elevating products from functional to experiential. Its custom fragrance polymers and advanced diffusion technologies transform products and spaces into immersive experiences. Brands across automotive, hospitality, retail and healthcare can enhance brand differentiation while enriching the user experience. Its portfolio features air fresheners for hospitality venues, workplaces and cars, along with odor neutralizers for offices and retail environments. It also includes scented cards for wardrobes, hotels, and vehicles, as well as automatic diffusers and adhesive fragrance solutions for packaging. “Our clients value the reliability and consistency of our fragrance polymers, as well as the customization capacity we offer,” says Angel Palacio, CEO and senior chief scientific officer. What distinguishes the company is its co-creation approach, where the team works closely alongside the client from the initial idea to the final product, resulting in trusted, long-term relationships. The white glove approach ensures that every solution meets the required technical specifications and delivers the intended sensory experience, helping clients strengthen customer loyalty. Custom-Engineered Polymers for Exceptional Brand Experiences Drawing on more than six decades of polymer expertise from its parent group, Scent Emotions possesses advanced know-how in compounding and transformation, which are instrumental in driving innovation in fragrance polymers and odor-neutralising technologies. The foundation enables it to apply accumulated experience to emerging technologies, such as compostable composites (ECO-HOPCP®), advanced microencapsulation, the integration of functional fragrances and the development of therapeutic fragrances for medical and healthcare sectors. The team combines technical tradition with continuous research to respond to diverse sectors. Since 2019, Scent Emotions has been operating its own compounding plant to develop fragrance polymers that are perfectly integrated and tailored to each specific application. It operates eighteen injection molding machines that run 24 hours a day, transforming materials into finished pieces while maintaining full control over every stage of the production process. The vertical integration provides key advantages, such as speed in development, maximum confidentiality, and precise control over release parameters, shape and durability.

Fine Chemical Manufacturing Company

In the world of life sciences research, where every experiment has the potential to unlock groundbreaking discoveries, meeting the demand for chemical ingredients is paramount. Whether it is common laboratory compounds, atypical reagents or custom-formulated solutions, research groups require prompt access to high-quality supplies. Oakwood Chemical is a leading manufacturer and distributor of fine organics that specializes in the rapid and efficient supply of research chemicals. Led by scientists, the company offers a dependable catalog service, holding approximately 40,000 distinct chemicals, with over 150,000 SKUs packaged and readily available for immediate shipment. It stands as a dependable supply chain partner for research groups to ensure their needs are consistently met, even in the face of challenges. “As experienced laboratory chemists, we understand the different critical needs of research groups and offer a varied range of customized services,” says Greg Butler, president.

Immersion Mills & Dispersion Equipment Company

What are the key considerations when procuring equipment for particle processing to meet industrial demands? Do you prioritize equipment efficiency, reliability, consistency, quality or durability? Hockmeyer has it all. Over a long-standing reputation of 80 years, Hockmeyer has established itself as a leader in Immersion milling and dispersion technology. It provides custom-designed processing equipment for mixing, blending, dispersing and particle size reduction. The equipment is recommended after a thorough assessment. A discussion between its R&D and processing experts and the clients allows Hockmeyer to understand their current processes and challenges in obtaining product specifications. Based on these insights, it formulates relevant recommendations. The company also proposes an attended trial at its testing facility, which allows it to assess the material firsthand, understand its behavior, determine the required horsepower and ascertain its rheology properties. This ensures precise design and customization of the equipment to meet client needs. Hockmeyer’s custom-designed equipment is used for developing inks, paints & coatings, adhesives, personal care products, renewable energy materials, and agrochemicals, to name a few. Material assessment and formulation verification improve the transition from laboratory to large-scale production. The company prioritizes flexibility in equipment development for a seamless transition from laboratory to production sizes. The equipment is designed to easily adjust according to batch sizes and accommodate changes in dimensions or incorporate vacuum operations, providing versatile solutions for diverse needs. This approach enables clients to optimize formulations and processes, reducing risks and enhancing product quality throughout the production lifecycle. Driving Efficiency through Streamlined Nano-Particle Processing Efficiency is paramount in particle processing, especially when dealing with nanometer-sized particles. Hockmeyer, recognizing the challenge, has made efficiency its hallmark. The research and development laboratory conducts extensive trials, adapting formulations for nano-sized particles to ensure peak performance and linear scalability with remarkable precision at a small scale. Hockmeyer’s mills demonstrate proficiency in handling media from 3mm down to 0.03mm. The equipment leverages high flow rates facilitated by maximizing the open surface areas of screens. The Inline Nexgen™ vacuum recirculation mill operates at high tip speeds and high flow rates, achieving tight particle distributions rapidly in recirculation mode, surpassing conventional horizontal mills.

CXO INSIGHTS

In the Tension Between Price Increases and Supply Chain Problems-With 3d Printing for Acute Problem Solving

Ralf Anderhofstadt, Head of Additive Manufacturing Solutions (AMS) Daimler Truck, Daimler Buses GmbH

3d Printing for Spare Parts and Tooling in Manufacturing is the Way to Go

Dr. Emmy Pavlovic, SVP Technology & Innovations, Bulten Group

Chemical Detection Analytical Advancements in Paper Packaging: Friend Or Foe?

Marcello Pezzi, Product Safety Director, DS Smith

Create a Solid Practice on How to Communicate

Rui Verissimo, Business Transformation Office - Project Lead, Honda Motor Europe Ltd

Freight audit & payment: money leakage or "just on budget"?

Anna Milanova, Sr. Manager E2E Network Intelligence, BIC S.A

Industry 4.0: Reimagining Manufacturing Operations

Thierry Wipff, Global Manufacturing Technology Engineering Tires, Continental

Transforming Biologics Manufacturing through Supply Chain Resilience

Veronique Kodjo, EVP of Global Manufacturing, Supply Chain and Quality, CEVA SANTE ANIMALE

IN FOCUS

The European Fragrance Revolution: Transforming Aromas with Custom Polymer Technology

Custom fragrance polymers in Europe offer innovation, sustainability, and personalisation, presenting significant opportunities for fragrance industry manufacturers.

Navigating Change: The Evolution of Chemical Consulting in Europe

Chemical consulting in Europe focuses on sustainability, regulatory compliance, digital innovation, and risk management to support the growth of safer, more efficient, and competitive industries.

EDITORIAL

Shaping the Next Era of Fragrance-Focused Polymer Innovation

At the core of this transformation is a new generation of microencapsulation and polymeric delivery technologies. These advanced systems are engineered to precisely control fragrance behaviour, enabling tailored volatility, on-demand activation and adaptability across diverse applications. The demand for sophisticated microcapsules and other delivery vehicles continues to grow as personal care, home care, and textile brands raise their expectations for long-lasting, consistent scent performance.

Yet this momentum brings its own set of challenges. Rising energy and raw material costs, increasingly stringent emissions targets, and evolving chemical safety regulations are pressuring manufacturers to modernise operations and strengthen supply-chain resilience. Europe’s fragrance market still remains vibrant, fuelled by an appetite for premium, personalised scent experiences, all of which rely heavily on precision-engineered polymer solutions. The result is a more mature and competitive landscape, where success hinges on sustainability, cutting-edge materials expertise and the agility to navigate a fast-moving regulatory environment.

This edition highlights the expert perspectives of Tom Salisbury, Director of Sustainability at GKN Automotive, and Martin Rößing, Plant Manager Arnstadt & Heidelberg, at BorgWarner. These esteemed professionals share their invaluable insights on developments and challenges within the sector, along with possible solutions.

We hope the valuable insights from industry leaders featured in this edition will help you make informed decisions for your businesses.