Thank you for Subscribing to Chemical Industry Review Weekly Brief

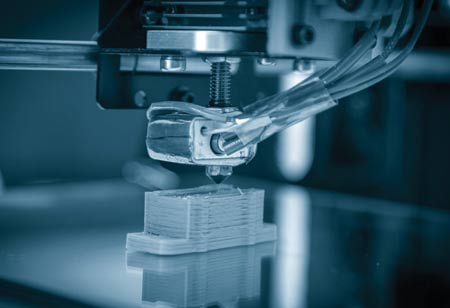

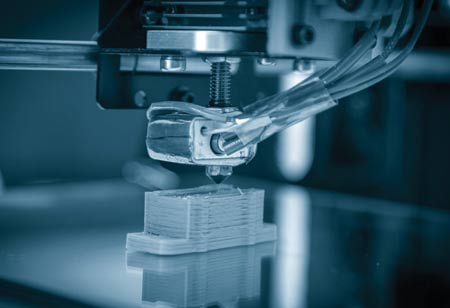

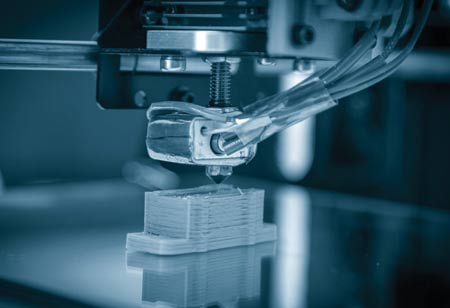

Christina Baker joined PPG in 2012 as a research and development chemist before transitioning to management roles, including global materials technology manager, in late 2016.Currently, she is leading the strategy development of PPG’s Ambient Reactive Extrusion (ARE) additive manufacturing (AM) technology. AM is the industrial manufacturing term used for 3D printing.

In conversation with Manufacturing Outlook, Baker discusses the innovative AREAM technology and how it can potentially disrupt the manufacturing industry. What pain points in AM can be stumbling blocks to the momentum it has gained in recent years? Advancements in different manufacturing methods and techniques are a huge challenge in itself. There have been constant stretches to figure out new approaches to make lighter-weight structures across industries. Having worked in the aerospace business, I am familiar with the challenges of using AM to create structures because of the limited choices in materials and the difficulty with some methods. For example, printing processes that create materials under high temperatures can introduce thermomechanical stresses and anisotropic mechanical performance. Our technology addresses the strain from shrinking during cool down by creating parts using a fully room-temperature process. PPG has an extensive portfolio of resins and a long, 138- year history of developing paints and coatings. Using that experience allows us to bring a wide variety of field-tested materials and bridge them into the AM space. What are your observations on the trends that are emerging in the additive manufacturing space? The most significant disruption is the shift from the traditional subtractive and molding manufacturing methods —for plastics and metals – into AM technologies. AM is demonstrated as viable, equivalent and sometimes even better in performance than the materials and processes in traditional methods. There is often a reduction in costs and waste during AM through the elimination of labor intense subtractive manufacturing steps. This typically results in sustainability improvements versus traditional processes. Additional benefits include elimination of bulky and expensive molds that have a long lead time. Manufacturing with a mold usually requires a large number of units for payback. If you are using AM, there is more flexibility in your design, especially if you may not be making that many units per year. Custom and high-end aesthetic options are also more viable. How do you envision the future of additive manufacturing in the next couple of years regarding all the potential disruptions and transformations that are happening? There are a lot of disruptions that are sure to follow in the space of AM. The additive manufacturing technology we use allows us to innovate in areas never imagined before. We can print a part that is large, with dimensions up to 10 feet or 3 meters in length, as well as airtight and watertight parts, which can be challenging with current plastic AM methods. ARE AM technology has potential for printing useable articles in one pass, where some technologies are more suitable for visualization and non-functional prototypes, or require further post-process smoothing or sealing. We also have a range of industrially relevant plastic materials, including those with proven long-term durability and functionality in harsh environments, which have the potential to fill gaps in material performance needs.. One of our focus areas in AM has been multi-material 3D printing. By integrating different types of resins through our AREAM technology, we can obtain a wide range of functionalities, such as printing embedded electronics. The technology also allows us to create articles that are covalently bonded throughout the whole structure, generating the z-axis adhesion required for mechanical strength and durability in many structural parts. e technology is equally of service in other advanced designs where you might need a flexible region and a rigid region in the article’s design. This combination would be a major advancement in the overall engineering space for bending and impact-resistant applications. Within the next few years, we hope to integrate our AREAM technology into production lines. This has the potential to reduce manufacturing production times, increase speed to market for our customers, and simplify processes as the technology is optimized for different applications. Flexible materials are one of many areas where PPG has found a lot of opportunity through ARE AM technology, which currently has limited options in the AM market. Our team has demonstrated printing flexible materials with enhanced mechanical properties versus conventional applications. Our portfolio of products have chemical, temperature, ultraviolet (UV) and weather-resistant capabilities – features that are critical in long-term environmental exposure applications. ARE AM technology is allowing us to save time, while often improving appearance and performance for our customers’ applications. Any piece of advice that you’d like to impart to your colleagues or aspiring professionals based on your experience? It’s been fulfilling to be a part of the ambient reactive AM world at its nascent stage. We have discovered firsthand the collaborative and supportive nature of the plastics AM segment. There is so much room for growth in AM, as the community is still fairly small. There is also recognition in the limitations of certain technologies. If you bring something new to the table, the community is excited about it and often willing to point toward where a new technology will provide the most value. It is very promising and underscores the importance of staying connected and supportive while being aware of what we are all able to bring to the table.I agree We use cookies on this website to enhance your user experience. By clicking any link on this page you are giving your consent for us to set cookies. More info